Is Teflon Tape Good for a Water Well System?

Introduction

Proper sealing in water well systems is crucial for functionality and longevity. This post evaluates the effectiveness of Teflon tape for water well systems.

Why Proper Sealing in Water Well Systems Is Crucial for Functionality and Longevity

Prevents Water Contamination

- Keeps Contaminants Out: Proper sealing ensures that external contaminants such as bacteria, pesticides, and surface water do not infiltrate the well system, protecting the quality of the water.

- Maintains Potability: A well-sealed system helps maintain clean, safe drinking water, especially for households and businesses relying on well water.

Avoids Leaks

- Water Loss Prevention: Effective sealing prevents leaks in the piping and fittings, ensuring the water reaches its intended destination without loss.

- Pressure Retention: Proper sealing is essential for maintaining pressure within the system, which is vital for the operation of pumps and water delivery.

Enhances System Efficiency

- Minimizes Energy Waste: Leaks or inefficient sealing can cause the pump to work harder to maintain pressure, increasing energy consumption and operational costs.

- Sustains Performance: Proper sealing ensures consistent water flow and pressure, which is critical for household and agricultural use.

Prevents Corrosion and Damage

- Protects Components: A well-sealed system minimizes the risk of moisture-related corrosion on metal parts like pumps and pipes.

- Extends Lifespan: By reducing wear and tear caused by leaks or pressure fluctuations, sealing contributes to the longevity of the system.

Handles Environmental Stresses

- Adaptability to Conditions: A properly sealed system can withstand temperature fluctuations, ground shifts, and other environmental factors that may otherwise compromise the system.

- Prevents System Failures: Sealing reduces the likelihood of breakdowns or costly repairs.

Compliance with Regulations

- Meets Standards: Many regions have strict guidelines on water well construction and maintenance. Proper sealing ensures compliance with these regulations, protecting users from legal and financial penalties.

Cost-Effectiveness

- Reduces Maintenance Costs: Preventing leaks and contamination through proper sealing decreases the need for frequent repairs or water treatment.

- Preserves Equipment: Well-sealed systems protect pumps, pipes, and other components, avoiding premature replacements.

Proper sealing is a fundamental aspect of water well system design and maintenance. Without it, the system risks inefficiency, contamination, and costly failures, undermining the investment and its reliability for the users.

What Is Teflon Tape?

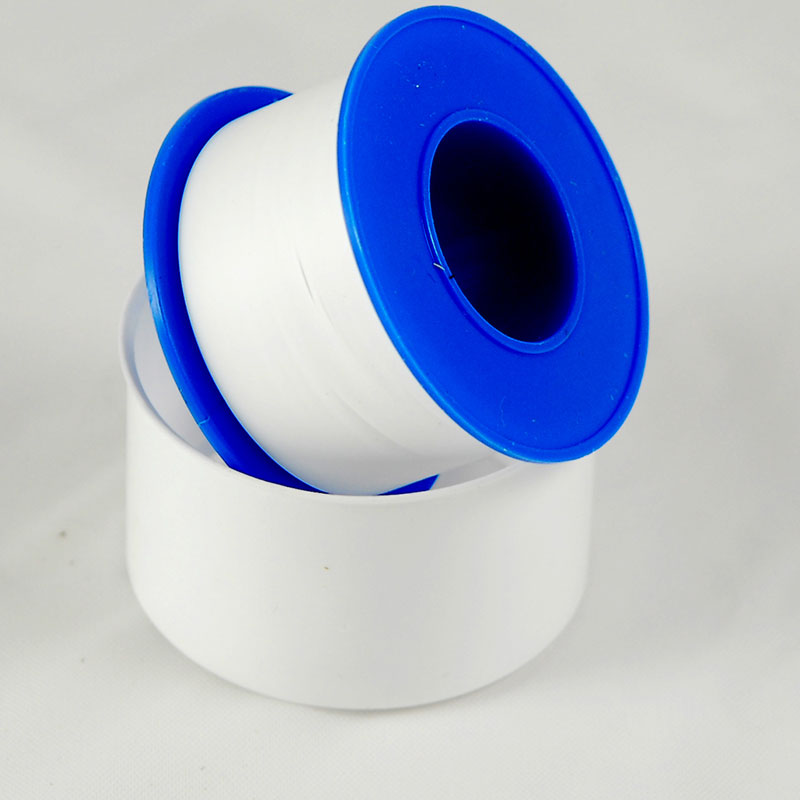

Teflon tape is a flexible, cost-effective sealing material commonly used in plumbing applications.

- Standard Teflon tape: General-purpose use.

- High-density tape: Suited for heavy-duty sealing.

- Yellow gas-rated tape: Used in gas applications.

Teflon Tape

Teflon tape, also known as plumber’s tape or PTFE tape (short for polytetrafluoroethylene), is a thin, flexible tape used primarily for sealing threaded pipe joints to prevent leaks. It’s commonly used in plumbing, gas, and water line installations.

Key Features:

- Material: Made from PTFE, a durable and non-reactive material.

- Heat and Chemical Resistance: Can withstand high temperatures and exposure to chemicals, making it ideal for a variety of environments.

- Flexible: Thin and easy to wrap around threads, allowing for a snug and secure fit.

Applications:

- Plumbing: For water pipes, faucets, and showerheads to ensure leak-proof connections.

- Gas Lines: Specialized versions (yellow PTFE tape) are used for gas line fittings.

- Aviation or Automotive: Sometimes used in hydraulic or pneumatic systems.

How to Use:

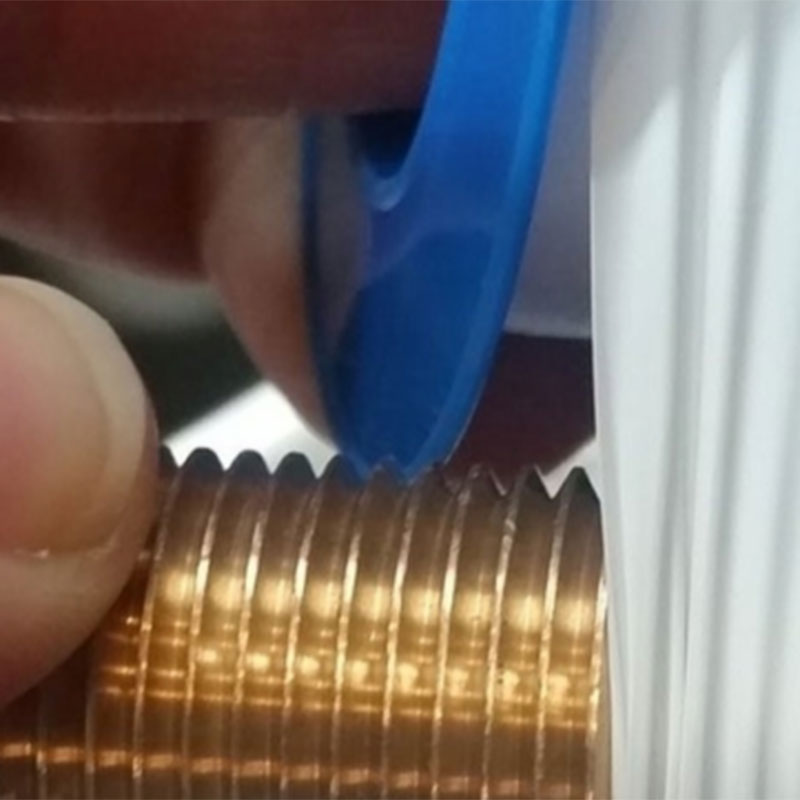

- Clean the Threads: Ensure the pipe threads are clean and dry.

- Wrap the Tape: Starting at the end of the threads, wrap the tape around in the same direction as the threads (typically clockwise) to prevent unraveling.

- Overlap Slightly: Overlap each wrap slightly, covering the threads completely.

- Tighten the Connection: Screw the fitting into place for a secure seal.

Different colors of Teflon tape often signify specific uses (e.g., white for general use, yellow for gas lines, pink for water lines).

Is Teflon Tape Good for a Water Well System?

Teflon tape, also known as thread seal tape or PTFE tape (polytetrafluoroethylene), is a common product used in plumbing to create a watertight seal on threaded pipe connections. But is it suitable for water systems? Let’s take a closer look.

Benefits of Using Teflon Tape in Water Systems

Effective Sealing

Teflon tape is designed to prevent leaks by filling the gaps between threaded fittings. Its malleable nature allows it to conform to the threads, creating a secure seal.

Resistance to Water and Corrosion

Teflon tape is highly resistant to water and won’t degrade or dissolve when exposed to moisture. Additionally, it helps protect metal fittings from corrosion by creating a barrier against water exposure.

Easy to Apply

Applying Teflon tape is simple. It involves wrapping the tape clockwise around the male threads of a fitting, usually two to three times, to ensure complete coverage before tightening the connection.

Compatibility

Teflon tape is compatible with most types of pipes, including PVC, CPVC, brass, and galvanized steel. It can be used in both cold and hot water systems, making it versatile for various plumbing needs.

Considerations When Using Teflon Tape

Not for High-Pressure Connections

While Teflon tape works well for most residential water systems, it may not be suitable for very high-pressure systems or industrial applications. In such cases, alternative sealing methods, such as pipe dope or specialized thread sealants, might be more appropriate.

Avoid Overuse

Overapplying Teflon tape can create too thick of a layer, potentially causing fittings to crack or threads to misalign. Proper application is key to avoiding issues.

Not for Compression Fittings

Teflon tape is designed specifically for threaded connections. It should not be used on compression fittings, as they rely on the compression of ferrules for sealing rather than thread engagement.

Use Certified Tape for Potable Water

For potable (drinking) water systems, it’s essential to use Teflon tape labeled as safe for potable water use. These tapes meet safety standards for contact with drinking water and ensure no harmful chemicals leach into the system.

Teflon tape is a reliable, cost-effective solution for sealing threaded connections in water systems. Its ease of use and effectiveness make it a staple in plumbing, especially for residential applications.

However, choosing the right type of Teflon tape and applying it correctly is crucial for ensuring a secure, leak-free connection. For more demanding systems or specialized applications, consider consulting a professional plumber to determine the best sealing method for your needs.

Teflon Tape Versus Other Sealing Compounds

Teflon Tape

- Material: Made from polytetrafluoroethylene (PTFE), a highly durable and slippery material.

- Application:

- Easy to use; simply wrap the tape around the threads in the direction of tightening.

- Ideal for smaller diameter pipes and fittings, typically used in plumbing and gas lines.

- Advantages:

- Clean and non-messy.

- Provides a lubricating effect, making assembly and disassembly easier.

- Resistant to a wide range of chemicals.

- Inexpensive and widely available.

- Limitations:

- Not suitable for non-threaded connections or large diameter pipes.

- Can shred during application if over-tightened, potentially causing blockages.

- Not a strong adhesive; relies on compression for sealing.

Other Sealing Compounds

Pipe Joint Compound (Thread Sealant)

- Material: Typically a paste-like compound made from various formulations, including silicone, PTFE-based, or solvent-based mixtures.

- Application: Spread evenly over the threads before assembly.

- Advantages:

- Provides a strong, long-lasting seal.

- Works on a variety of materials, including metal and plastic.

- Does not shred or tear.

- Available in different formulations for specific applications (e.g., high temperature, chemical resistance).

- Limitations:

- Messier to apply compared to tape.

- May require curing time before full effectiveness.

- Can be more expensive than tape.

Anaerobic Sealants

- Material: Specialized compounds that harden in the absence of air.

- Application: Used in high-pressure systems or industrial applications.

- Advantages:

- Very strong and durable seal.

- Resistant to vibration and shock.

- Limitations:

- Requires a clean surface for application.

- More expensive and complex to use than Teflon tape.

Comparison

| Feature | Teflon Tape | Sealing Compounds |

|---|---|---|

| Ease of Use | Simple, no mess | Slightly more effort, can be messy |

| Durability | Moderate | High |

| Suitability | Smaller, low-pressure systems | Larger, high-pressure systems |

| Cost | Low | Moderate to high |

| Temperature Range | Moderate | Wide (depends on formulation) |

When to Use

- Teflon Tape: Residential plumbing, low-pressure water or gas connections, and when a clean and quick solution is needed.

- Sealing Compounds: Industrial applications, high-pressure systems, or situations requiring a robust, long-lasting seal.

Is Teflon Tape Good for a Water Well System?

Best Practices for Using Teflon Tape

Choose the Right Type of Tape

- Standard Teflon Tape (White): Suitable for general plumbing, including water and air lines.

- Yellow Tape: Designed for gas lines.

- Pink Tape: Used for water lines in high-pressure systems.

- Green Tape: Designed for oxygen lines (oil-free and grease-free).

Prepare the Threads

- Clean the Threads: Ensure the threads are free of dirt, debris, grease, or old tape. Use a wire brush or rag to clean the threads if necessary.

Apply the Tape Correctly

- Wrap in the Right Direction: Wrap the tape clockwise (in the direction of the threads) to ensure it stays tight when you screw the fitting in place.

- Start a Few Threads Back: Begin wrapping about two threads from the end of the pipe to avoid having tape inside the pipe, which can break off and clog the system.

- Overlap and Stretch: Overlap the tape slightly with each wrap and stretch it tight for a snug fit.

Use the Right Amount

- Wrap 2–3 Layers: This is usually sufficient for most applications. Too much tape can make it difficult to screw the fitting in, while too little might not seal properly.

Avoid Over-Tightening

- Snug, Not Over-Tightened: Over-tightening can damage the threads or the connection, defeating the purpose of the seal.

Test the Connection

- Check for Leaks: After assembling, test the system for leaks by turning on the water, gas, or air and observing the connection. Tighten further if necessary.

Avoid Certain Applications

- Not for Compression Fittings: Teflon tape is not suitable for compression fittings, as these rely on metal-to-metal contact for sealing.

- Avoid Overuse on Small Threads: Excess tape on small-diameter threads can make assembly difficult and lead to over-tightening.

Store Properly

- Keep It Dry and Clean: Store the tape in a clean, dry area to maintain its adhesive properties and integrity.