Understanding Water Well Pump Electrical Wiring: A Comprehensive Guide

Proper electrical wiring is essential for the safe and efficient operation of a water well pump.

Incorrect wiring can lead to malfunctions, safety hazards, or even damage to the pump system.

Whether you’re installing a new pump or troubleshooting an existing one, understanding the basics of water well pump electrical wiring is critical.

In this guide, we’ll explore key components, wiring steps, and troubleshooting tips to help ensure your system runs smoothly.

Basics of Water Well Pump Electrical Wiring

Water well pump electrical wiring is the backbone of your pump system. It provides the power needed for the motor to draw water from the well and deliver it to your home or property.

Understanding the key elements of this wiring system helps you maintain, troubleshoot, or install it effectively.

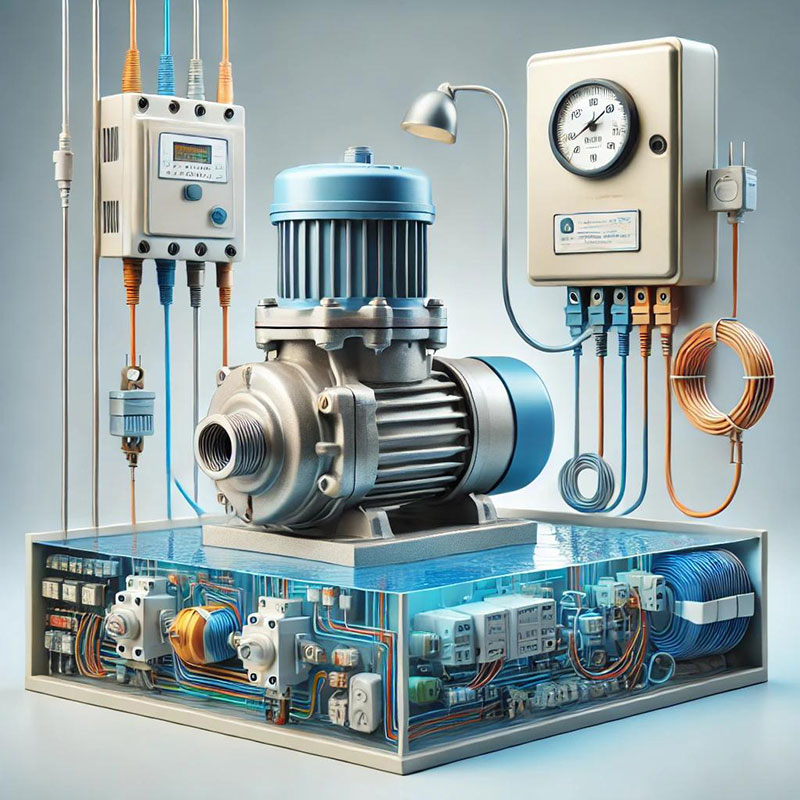

The main components involved in water well pump electrical wiring include the pump motor, control box, pressure switch, and breaker panel.

A well pump system may use either a 2-wire or a 3-wire configuration, depending on the pump type and motor design.

In general, 2-wire systems are simpler, as they do not require a separate control box, while 3-wire systems provide greater flexibility and are typically used for larger pumps.

Common Components in a Water Well Pump Electrical Wiring System

To understand how a water well pump operates, it’s important to be familiar with its key electrical components:

- Pump Motor: The pump motor converts electrical energy into mechanical energy to draw water from the well and distribute it through your plumbing system.

- Control Box: Found in 3-wire systems, the control box houses components like the capacitor and relay, which manage the pump motor’s start and operation.

- Pressure Switch: This device monitors water pressure and automatically turns the pump on or off to maintain consistent pressure in your water system.

- Breaker Panel: The breaker panel supplies power to the pump system and provides overload protection to prevent electrical hazards.

- Wiring Types: Electrical wires are typically color-coded: red for live wires, black for neutral wires, and green for ground wires. Proper connections are essential for safe and efficient operation.

Steps for Wiring a Water Well Pump

Wiring a water well pump requires careful planning and adherence to safety standards. Here are the key steps involved:

- Safety Precautions: Begin by turning off the power at the breaker panel to avoid electrical shocks. Use insulated tools and ensure you follow local electrical codes.

- Connecting the Breaker Panel to the Pressure Switch: Run wires from the breaker panel to the pressure switch. Connect the live, neutral, and ground wires to the appropriate terminals on the switch.

- Wiring the Pressure Switch to the Control Box: For 3-wire systems, connect the pressure switch to the control box using color-coded wires. Ensure the connections match the labels on the box and the manufacturer’s instructions.

- Connecting the Control Box to the Pump Motor: Run wires from the control box to the well pump motor. Follow the wiring diagram provided by the pump manufacturer for correct connections.

- Grounding the System: Properly ground the entire system to protect against electrical surges and ensure safety. Use a ground rod if necessary.

Double-check all connections and ensure they are secure before restoring power.

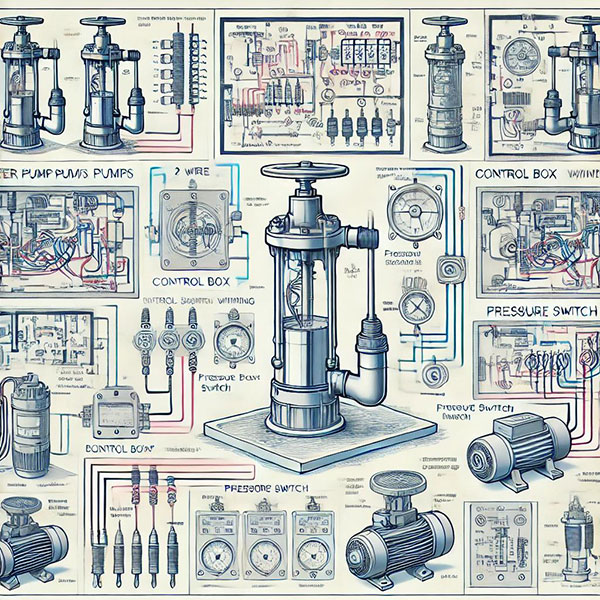

Wiring Diagrams and Configurations

Wiring diagrams are essential for ensuring correct installation. They provide a visual guide to connecting components and help avoid mistakes. The two main configurations for well pumps are:

- 2-Wire Systems: In these systems, the pump motor connects directly to the power supply through the pressure switch. There is no separate control box, making installation simpler but limiting flexibility.

- 3-Wire Systems: These systems include a control box, which contains start and run capacitors for the motor. The additional wire allows for better motor control and is used for larger pumps or deeper wells.

Always refer to the manufacturer’s water well pump electrical wiring diagram for your specific model.

Troubleshooting Common Wiring Issues

If your water well pump electrical wiring isn’t working correctly, wiring issues may be to blame. Common symptoms and causes include:

- Pump Not Starting: Check for loose connections, tripped breakers, or a faulty pressure switch.

- Inconsistent Operation: Inspect the control box for damaged capacitors or relays. Ensure all wires are securely connected.

- Low Water Pressure: Verify that the wiring to the pump motor is intact and providing sufficient power.

- Frequent Breaker Trips: Look for short circuits, damaged wires, or an overloaded pump motor.

Always turn off the power before troubleshooting and consult a professional if the issue persists.

Importance of Hiring a Professional

While some homeowners may feel comfortable handling basic electrical work, wiring a water well pump is a complex task that requires expertise. Hiring a licensed electrician or water system professional offers several advantages:

- Expertise: Professionals understand the intricacies of well pump systems and ensure proper connections and safe operation.

- Safety: Working with electricity and water poses significant risks. Professionals are trained to handle these hazards safely.

- Warranties: Many contractors offer warranties on their workmanship and the components they install, providing peace of mind.

While professional installation may involve higher upfront costs, it prevents mistakes that could lead to expensive repairs or safety hazards in the future.

FAQs About Water Well Pump Electrical Wiring

- How do I know if my well pump wiring is faulty? Look for signs like the pump not starting, inconsistent operation, or frequent breaker trips. A professional inspection can confirm the issue.

- What is the difference between 2-wire and 3-wire well pumps? 2-wire pumps connect directly to the power source, while 3-wire pumps use a control box for enhanced motor control.

- Can I wire a well pump myself? While possible for experienced individuals, it’s recommended to hire a professional to ensure safety and proper installation.

- What safety precautions should I take when working with well pump wiring? Always turn off the power, use insulated tools, and follow local electrical codes.

- How often should well pump wiring be inspected? Annual inspections are recommended to catch potential issues early and ensure optimal performance.

Conclusion

Proper water well pump electrical wiring is crucial for the safe and efficient operation of your system.

From understanding components to troubleshooting issues, this guide provides the knowledge you need to maintain your system effectively.

For complex installations or repairs, hiring a professional ensures the job is done safely and correctly.

Don’t leave your water supply to chance—invest in proper wiring to keep your system running smoothly for years to come.